HIO-technology®

PROBLEM & SOLUTION

Capillary moisture is present in all old building structures which don’t have horizontal hydro-isolation in their base walls or if the implemented insulation has degraded over time. Special mortar, penetrating compounds, wall covering with various linings, wall injecting with solutions in combination with drying mortars only solve the problem temporarily because after two-three years the procedure needs to be repeated.

The only way to stop the capillary moistening is complete wall cutting and implementation of a new horizontal waterproof barrier, paying attention not to cause wall shuffling or uncontrolled cracking of the walls along the process, which is bound to happen when the wall is completely cut.

HIO-TECHNOLOGY® IS THE BEST CHOICE!

HIO-technology® is the only method of permanent protection from capillary moisture which doesn’t endanger the building structure construction and stability by complete wall cutting. Moist walls, regardless of their thickness (2, 3, 5 and more meters) or the type of building material (bricks, all kinds of stone, mixed materials) are completely cut through with ultrafast diamond cutting tools, in small stages, without vibrations and shakes. Special mass of extraordinary adhesion is injected in such cuts through which, as a new layer of horisontal hidro-isolation, one after the other, HIO-master barriers® are implemented. Each barrier(lamella) contains male and female hook, which allows easy binding and formation of uninterrupted waterproof barrier in the wall.

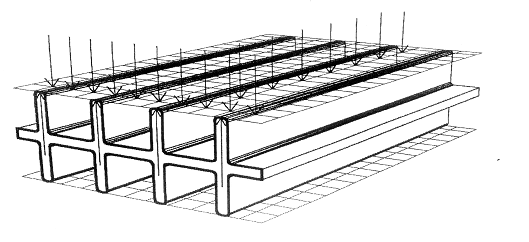

HIO-master barrier® is unique because thanks to its shape (vertical ribs) and the implementation procedure (Flaps are adjusted according to the height of the cut) it prevents wall shuffling! Flaps height of each individual lamelle is ground from 13mm (original height), and therefore precisely shaped to the measured height of the cut, while the wertical wings take over the complete weight load of the upper parts of the structure, without any deformations.

HIO-TECHNOLOGY® PROCEDURE

All the research, static calculations, testings and analysis confirm that HIO-technology® doesn’t endanger stability and the construction of the structure and it doesn’t have side effects. Up to now, HIO-technology® has been used to permanently rehabilitate a couple of hundreds of structures (mainly protected cultural property) which live their new lives today, standing as a proof of its eficiency, longevity and safety.

Click to read more

CAPILLARY MOISTURE IS OLD STRUCTURES’ WORST ENEMY

Capillary moisture is the worst enemy of all the old building structures which don’t have any type of horizontal hydro-isolation in their base walls or if the implemented insulation has degraded over time. Unobstructed moisture from the ground rises upward into the superstructure and causes damage and destruction of building material.

HOW TO STOP MOISTURE – COMPETITION

Various types of vapor permeable mortar are available on the market nowadays, but they don’t remove the cause of capillary moisture (no horizontal insulation in walls). They just temporarily solve the problem which as a consequence causes damp mortar and ugly moist stains. After appliance of new vapor permeable mortar, the structure looks nice, but after two-three years the whole procedure need to be done again which devaluates all the invested effort and resources.

Injection of walls with different approaches such as drilling holes in various diameters and depths on the both sides of the wall is not a method reliable enough because after crystallization it is impossible to evaluate whether the wall has formed an uninterrupted waterproof barrier or not. Because of a large number of holes which are filled only on the entry points, the stability of the building structure is severely endangered.

MECHANICAL CUTTING

The only way to effectively stop capillary moisture is complete cutting of the wall and implementation of a new horizontal waterproof barrier. All the mechanical cutting methods efficiently stop penetration of capillary moisture, but as an unwanted consequence they can cause uncontrolled object shuffling and wall cracking.

This method’s primary problem is that the cutting heights are variable, depending on the type of cutting chain and the devastation degree of the building material. Height of one lining can vary from 8-13mm! All the other mechanical wall cutting methods (with exception of HIO-technology®) use rigid fiberglass panels for isolation, bitumen or PVC tape of thickness 2mm do 6mm. When the 2mm thick isolation is implemented (HDP isolation is particularly popular in Hungary) into a 13mm cut opening (diamond cord with 11mm beads makes a 12-13mm cut), it leaves a 10mm or 7mm gap in the cut opening if PVC lamella of 6mm height is used. In order to avoid object shuffling and wall cracking, wooden or plastic pads of various thickness and length are inserted on both sides of the wall into the cut. As the pads are inserted only 20-25cm deep into the wall, they can prevent wall shuffling up to 50cm on one story buildings. Multi-story buildings and walls of greater thickness, especially thick, massive walls (1, 2, 3m and more) are left unsupported in the core, which causes sporadic shuffling and occurrence of wall cracking.

This is what happens when “something similar” is implemented instead of HIO-master barrier®.

HIO-TECHNOLOGY® – THE ULTIMATE SOLUTION

HIO-technology® is the only method of permanent protection from capillary moisture which doesn’t endanger the building structure construction and stability by complete wall cutting. Moist walls, regardless of their thickness (2, 3, 5 and more meters) or the type of building material (bricks, all kinds of stone, mixed materials) are completely cut through with ultrafast diamond cutting tools, in small stages, without vibrations and shakes. Special mass of extraordinary adhesion is injected in such cuts through which, as a new layer of horisontal hidro-isolation, one after the other, HIO-master barriers® are implemented. Each barrier(lamella) contains male and female hook, which allows easy binding and formation of uninterrupted waterproof barrier in the wall. Svaka šina (lamela) ima mušku i žensku kopču što omogućava lako povezivanje i formiranje neprekinute vodonepropusne barijere u zidu.

HIO-MASTER BARRIER® IS UNIQUE

HIO-master barrier® prevents shuffling thanks to its shape (vertical ribs) and the implementation procedure (Flaps are adjusted according to the height of the cut)! Flaps height of each individual lamelle is ground from 13mm (original height), and therefore precisely shaped to the measured height of the cut, while the wertical wings take over the complete weight load of the upper parts of the structure, without any deformations.

HIO-master barrier®is made of PVC with additives for better quality, and as such it persists all the chemical influence and has unlimited expiration date when implemented. It is laboratory tested and attested. static security calculation confirms that HIO-technology® application does not endanger the load capacity of the walls for the effect of vertical and horizontal loads, so it doesn’t question either local or general wall stability, as well as the entire object. HIO-technology®, thanks to HIO-master barrier® doesn’t contain pads, doesn’t cause shuffling of cracking walls!

INJECTING

A very important segment of HIO-technology® is injection of the cuts which is performed under 30 Bar pressure. Thanks to the special needle which penetrates deep into the cut (this is also our own technological innovation) and high pressur the injecting mass optimally fills the cut and the barrier profile. The mass has great adhesion and after solidification it creates an unbreakable bond in the wall together with the barrier – a new coupling, stronger than any other previous mortar bond. Because of its features, the new cupling is resistant to seizmic disorders.

HIO-TECHNOLOGY® IS THE BEST CHOICE!

All the testing, static calculations, tests and analysis confirm that HIO-technology® doesn’t endanger stability and construction of the building structure and it doesn’t cause unwanted effects. Up to now, HIO-technology® is used to permanently rehabilitate more than 400 churches, hundreds of various structures (mostly protected cultural property) which live their new lives today, proving its efficiency, longevity and security.